We are Manufacturer, Supplier, Distributor, Trader, Exporter, Importer, Maintenance Hardness Case Depth Tester and our setup is situated in Pune, Maharashtra, India.

Leading Distributor / Channel Partner of Hardness Case Depth Tester from Pune.

In cooperation with the Fraunhofer Institute for Non-Destructive Testing (IZFP), Q NET Engineering GmbH has developed an ultrasonic test instrument for fast and easy SHD control.

Reduced efforts and costs for testing facilitate rapid production control for a consistently high level of quality. The test instrument is used to optimtzemanufacturing parameters, reduce down times after inductor changes, for production monitoring and quality control.

The spectrometer provides high speed in determining chemical elements: C, Si, Mn, Cr, Ni, Fe, Mg, Al, V, Cu, Zn, Sn, Mo, Ti, W, Nb, Pd, Ag, Cd, Pt, Au and others.

METHOD

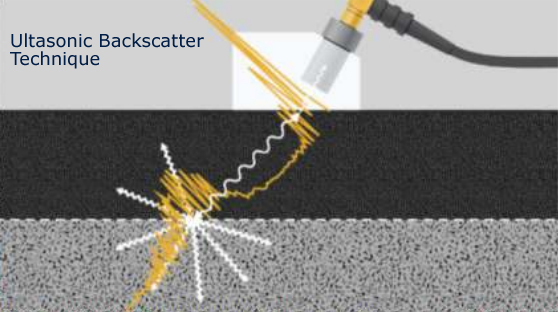

The test method is based on the effect that the hardened layer is almost transparent to ultrasonic waves while the non-hardened material scatters them back. The backscattered signal received by a probe. Is processed by the UT hardware and automatically evaluated by the software. The Surface Hardening Depth (SHD) is calculated and displayed by the software.

In most cases the results comply with the results of destructive methods_ SHD values 8Lgt 1.2 mm are determined using standard equipment. Lower SHDs can be tested with special probe systems.

Advantages :

• short set-up times

• simple, uncomplicated calibration

• fast and easy scanning

• high test sensitivity

• comfortable sensor handling

• sensor adaptable to complex geometries

• visualization of the current test point

• testing at small radii and undercuts possible

• individual report templates

• storage of results in data base

• analysis and revaluation of test results

• line scans and circumferential scans

• automation possible