We are Authorized Dealer of FIE, Manufacturer, Supplier, Distributor, Trader, Exporter, Importer, Maintenance, AMC Services Provider of Balancing Machines, Dynamic Balancing Machines, HDCM Dynamic Balancing Machines, Vertical Balancing Machines, Auto Correction Vertical Balancing Machines and our setup is situated in Pune, Maharashtra, India.

We are a leading Distributor / Channel Partner of dynamic balancing machines, hdcm dynamic balancing machine, vertical balancing machine and dynamic balancing machine from Pune, India

Hard Bearing Models : HDM

Machines Model HDM are horizontal type universal hard bearing balancing machines provided with Microprocessor based measuring panel HDM-8500 for balancing different shapes of rotors like rotors of electrical machines, crankshafts, cylinders, Gas Compressors, flywheels, turbine rotors, rotors of centrifugal pumps and any other type of rotors of rotating machines.

These machines feature a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, measures and stores the unbalance values on DPMs for two planes simultaneously and stops machine (with brake if machine is provided with electrical braking facility). The measuring cycle in general is less than 10 seconds for normal rotors, which can be accelerated within 5 seconds.

To have smooth and gradual acceleration models HDM 3,000/7,000/10,000/20,000 are provided with slip ring motors in order not to have damage to drive coupling as well other rotating parts in drive system like gears etc. The starting of these machines is done manually by cutting remittances of starter in 4 to 5 steps.

Key-board facility provided on measuring panel for correct data feeding of rotor with 1 digit accuracy for its dimensions like A, B, C, R1 & R2. Tolerance limits of both correction planes i.e. t1, and t2 can be fed, so that when rotor is balanced within the limits respective LED is glow up, indicating no further correction necessary. For other details please refer Features of Measuring panel HDM-8500.

The usable length of machine is established according to the longest rotor to be balanced. Extension beds can be supplied on request, which can be added to standard bed of machine. It is also possible to install an additional bed (Gap bed) with a pit between this bed and standard bed of machine in order to balance rotors having its outside diameter exceeding swing over standard bed. Models HD-7,000/10,000/20,000 are provided with fixed separate drives and hence gap-bed design is not possible.

| Product Details | |

| Minimum Order Quantity | 1 Number |

| Weighing Capacity | 50-100kg, Above 100 |

| Brand | FIE |

Features :

Digital display for unbalance indicationAmount and angle for unbalance for both planes displayed on

separate DPMS. Hence linear accuracy is very good as compared to Analog meter. Accuracy ±1 Digit for

amount and ±1 Degree for angle.

Digital display for RPM indicationA DPM is provided to indicate balancing speed continuously as a

standard feature.

Auto Stop No necessary to stop machine once started. It stops automatically after stabilization of

unbalance results.

Simultaneous Indication Amount and Angle of unbalance in both planes displayed simultaneously and

remains displayed (Stored) till next run. This totally eliminates operation of plane selector and

reduces additional time for stabilization of readings in other plane.

Key-board Data of rotor dimensions and balancing tolerance i.e. values of A, B, C, R1, R2, tl1, tl2,

are fed by key operation. Hence accuracy of data feedings accurate upto 1 digit.

Tolerance Indicators Separate LEDS are provided for both planes which glow when unbalance is reduced

within balancing tolerance.

Auto-range Depending upon whether unbalance amount is more or less a respective course or fine range

gets automatically selected till rotor gets balanced within tolerance limits. Multiplier operation is

totally eliminated.

Data Store Data of various rotors can be stored against respective rotor type nos. Hence no need of

measuring of rotor dimensions or rotor data feeding when repeat balancing operation required.

Just call rotor type no. and machine is ready for balancing.

Self Check Panel is provided with “Self-Check” mode which checks proper functioning of digital

displays, LEDs is cyclic operation. This helps immediate fault detection.

Dynamic Balancing Machines With Micro Processor Based Measuring Panel

Model - HDCM 300

Features:

Digital display for unbalance indication

Amount and angle for unbalance for both planes displayed on separate DPMS. Hence linear accuracy is

very good as compared to Analog meter. Accuracy ± Digit for amount and ± Degree for angle.

Digital display for RPM indication

A DPM is provided to indicate balancing speed continuously as a standard feature.

Details :

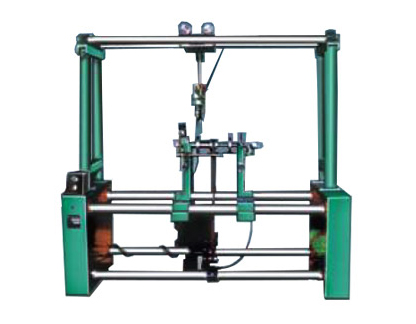

Machines model HDCM are belt driven horizontal type photo scanning Universal Hard Bearing Balancing Machine, provided with microprocessor based measuring panel HDCM – 8500 suitable for balancing different shapes of rotors, of electrical machines, Cylinders, fly wheel, rotor of centrifugal pumps and other type of rotating machines. These machines are very simple in design, No drive coupling/adaptor etc. required to connect to the rotor to be balanced.

It has following advantages

- Cost saving on manufacturing of precision adaptor to connect drive coupling to rotor.

- Any rotor can be balanced without losing time in manufacturing of adaptor.

- The balancing accuracy of rotor not disturbed due to unbalance in drive coupling/adaptor.

- Belt drive machine are more accurate (about 5 times) as compared to end drive machine.

The machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, measures and stores the unbalance values on DP Ms for two plane simultaneously and stops machine. Key board facility provided in measuring panel for correct data feeding of rotor with 1 digit accuracy for its dimensions like A, B, C, R1 & R2. Tolerance limits of both correction planes i.e. +11 & +12 can be feed so that when rotor is balanced within the limits respective LEDs glow up, indicating no further correction necessary. For other details please refer "features of measuring panel HDCM-8500".

Vertical Single Plane machine with Optional Vertical or Horizontal Drill Head Attachment.

HDVM 8500

This Microprocessor based measuring panel suitable for FIE Vertical Single Plane Hard Bearing Balancing Machine.

Hard Bearing Models : HDVM & HDVTM

Machines Model HDVTM are Vertical type single plane Hard Bearing Machine provided with Microprocessor based measuring panel HDVM-8500 for balancing Disc shaped rotors such as Clutch plates , Fan Blades, Fly wheels, Magnetos, Grinding wheels, Impellers etc. Where as HDVTM are Vertical type two plane hard bearing machines provided with Microprocessor based measuring panel HDVTM-8500 for balancing spinning pots, Spinning spindles etc.

Both type machines feature a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, measures and stores the unbalance values on DPMS and stops machine.

Key Board facility provided on measuring panel for correct data feeding of rotor with one digit accuracy for its dimensions like 'RAD', +1 for single plane & w,d,rl,r2+11,+12 for two plane machines. When rotor is balanced within the limits respective LEDs glow up, indication no further correction is necessary.

For other details please refer standard features of measuring panel HDVM and HDVTM. Both type of machines are provided with electronic companion software to compensate the unbalance effect due eccentricity between rotating (Spindle) axis & adaptor (Rotor) axis.

Features :

Digital display for unbalance indication

Amount and angle for unbalance for both planes displayed on separate DPMS. Hence linear accuracy is very good as compared to Analog meter. Accuracy ±1 Digit for amount and ±1 Degree for angle.

Digital display for RPM indication

A DPM is provided to indicate balancing speed continuously as a standard feature.

Auto Stop

No necessary to stop machine once started. It stops automatically after stabilization of unbalance results.

| Product Details | |

| Minimum Order Quantity | 1 Number |

| Weighing Capacity | 1-10kg |

| Usage/Application | BALANCING MACHINE |

| Brand | FIE |

| Accuracy | AS PER ASTM |

| Power | 440V |

| Frequency | 50 HZ |

| Phase | 3 PHASE |

Features :

Standard Features of control panel

1. DSP controller based processing

2. Digital display for unbalanc indication

3. Digital display for RPM Indication

4. Auto –Stop

5. Simultaneous indication

6. On screen keyboard

7. Tolerance indicators

8. Data Storage

Operation Cycle -The working cycle is fully automatic with unbalance indication while rotor running

and after stopping the balancing cycle it precisely rotates to its correction position, further

Vertical drill head cycle starts for correction and asks for following parameters

1. Material Density

2. Drill Size

3. Maximum drill depth

4. Allowed no. of holes

5. Center distance between two hole