We are Manufacturer, Supplier, Distributor, Trader, Exporter, Importer, Maintenance, AMC Services Provider of Ultrasonic Flow Detector and our setup is situated in Pune, Maharashtra, India.

Always Free hands - nothing extra

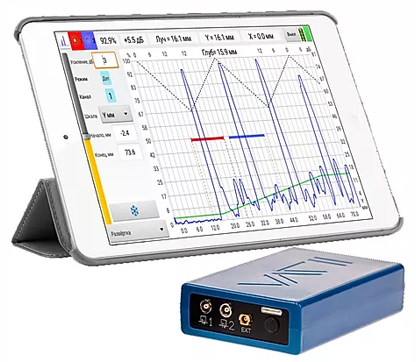

Veiograph II is an ultrasonic flaw detector with a tablet or a smart phone used as a screen. Main work flows for testing and thickness measurement: metal and polyethylene pipelines, metal and polyethylene welded Joints. A serlous device that Is as easy to use as a smartphone

All settings with one hand - quickly and Intuitively. There are no cables between you and the screen. Nothing prevents you from comfortably doing work, no matter where you are. At altitude. under difficult weather conditions, at low temperatures. It charges fast and holds charge twice as long. Think about your Job, not your tools.

Easy to use as Smartphone

Screen Size - user selectable, from Smartphone to Tablet Most compact (100mm X 68mm X 26mmiand Light weight (165 gm) in Industry.

• Wireless connectivity between display and device.

• Brightness adiustment depending on the lightning.

• Automatic report generation.

• Unlimited DATA Storage. Presence of envelop function.

• DVG. DAC, AWS D1.1 makes it powerful device.

• Immediate software update by Google Play.

• No need to watt to developer forweeks.

• Supported by GPS and digital signature to increase efficiency and productivity.

Low Temperatures

Ultrasonic flaw pattern UD9812 “Uralets” is made to perform a manual ultrasonic testing of any of plastic and metal articles having a different thickness (range 0.5 mm to 6000 mm) for the presence of abnormalities of homogeneous structure and continuity. Using the device this model can carry out the control of welded joints, semi-finished products, and forging and castings. UD9812 instrument measures the time delay values of the ultrasonic signals, the magnitude of the defect and the ratio of signal amplitudes.

In order to detect various types of defects in the material of the object by using ultrasonic wave ultrasonic flaw detector. Its action is based on an analysis of the arrival time of the ultrasonic waves reflected from defects, ie internal irregularities ,. It measures not only the arrival time, but also the waveform, amplitude, and much more. Flaw detector allows us to see in the test object, any deviations from the norms and various defects.

Description

• Ultrasonic Flaw UD9812 “URALETS” developed researcher of the Russian Academy of Sciences. After

summarizing the experience of ultrasonic non-destructive testing, resulting in 80-90 years in the engineering and

energy sectors was developed by Russian scientists flaw of this model.

• Most of the questions that arise from the experts on NDT in choosing rassmatrivamyh devices and carrying out

quality control of welds in UD9812 “Uralets” taken into account by developers. The design, look and UD9812

specifications carefully designed by professionals in the field of electronics and physics and instrumentation.

• Ultrasonic Flaw most lightweight, weighing less than 1240 g.

• A membrane keyboard, which has a high wear resistance to aggressive media. Thanks to the sophisticated design

of the buttons under no foreign contaminants falls (oil, dirt), so that the buttons are not damaged.

• The connectors do not interfere during the working process, as are the rear panel.

• For ultrasonic flaw UD9812 Uralets made only multicore cables with a soft coating of polymers and thermally

stable dope protective silicone to prevent abrasion.

• Built-in ultrasonic flaw color display can be seen even in bright sunlight (function «SunLight Readable»). This

development involves the use of the instrument in environments with different external light from the bright

summer light to artificial or weak shadows.

• The power supply fuse is “self-healing” function. With frequent jumps voltage fuse triggered, and the device itself,

however, remains outside the danger zone when working on batteries in stand-alone mode. Especially useful this

function is in large halls with energy-intensive welding oboroduvaniem And even more convenience for NDT

training, and for the organization of the automated operational ultrasonic testing is a link via USB in real time with

electronic devices

• Electro-acoustic path of the ultrasonic flaw detector Uralets UD9812 (sounding pulse generator and receiver)

supports a variety of ultrasonic transducers having the agreed rate from 0.6 to 12 MHz. Separately, the UD9812

will work with foreign frequency converter “Sonatest” brands “Panametriks”, “Krautkramer

The main distinctive features

• Several ways to the depth settings, “Spreadsheet” and more universal – “Avtoraschet”.

• time sensitivity adjustment mode “theoretical calculations” (replacing DGS diagrams, scales ARD).

• Built-in gauge mode that allows you to measure the data signal transition through the zero mark.

• The built-in voice recorder.

• Communication with a personal computer via a USB 2.0 (allowing real-time on the computer to see the flaw

detector screen).

Technical advantages of the UD9812

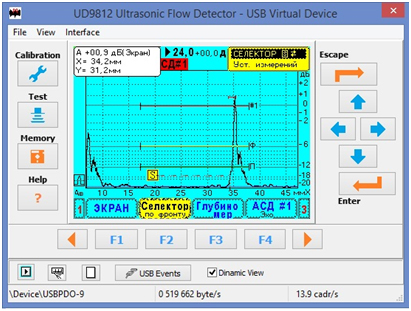

You see printskrin pilot version of the new program “Virtual flaw UD9812”

Virtual flaw UD9812 program allows a computer to remotely see what is happening on the flaw detector, as well as control buttons flaw.

Innovation – a scalable window, Russian and English interface, enhanced data display speed. To communicate with the device UD9812 need a USB driver, which is installed with a standard software package, see. Above. The “virtual flaw” works in 32 and 64-bit Vista operating system, Windows XP, 7, 8,10.

Technical features of the UD9812

• Fully digital signal processing: RF filtering, detection, smoothing, noise cutoff, DAC and measuring the echo

characteristics.

• The accuracy of measurement of time delay signals ± 0.006 ms.

• Support for any frequency consistent with the probe of 0.6 to 12 MHz.

• Two modes: Setup and control.

• Intuitive windowed user interface with built-in help system.

• Volatile memory for device settings and monitor results.

• Support for text and voice comments to the control data.

• It contains a set of software for the PC, which allows you to broadcast an image UD9812 screen on a PC monitor

in real time, to create reports of any form of USI, save A-scans in files (Math-Cad, text and binary) for use in scientific research purposes .

• UD9812 System (SDA TCG, scan, etc.) work independently. Changing the parameters of one system does not

affect the rest setting

• Two independent SDA (work echo or shadow method)

• ASD levels are tied to the sensitivity of the device (the device does not require readjustment when changing the

sensitivity)

• Measuring the delay parameters of echoes produced: along the front, at the peak, the transition through zero

(ultrasonic thickness gauge mode)

• Two signal display mode: HF and detected

• Two ways to the depth setting: tabular and avtoraschet (SOP notched)

• The ability to measure the parameters of the signal in the still mode (frost)

• fixation mode echo superposition current signal (used in difficult situations of defect discriminating signals and

spurious signals)

• ultrasonic thickness gauge mode with echo control and recording of measurement results

• mileage recording function echo envelope and determine the size of conventional

• Two ways TVG setting: traditional (in points) and theoretical calculation (based on ARD in the far field)

• An one interface to read the PEP information (type, number and parameters PEP). Each converter is supplied with

a flaw, contains a built-in memory chip, which recorded the type, number and its parameters. On the basis of these

data is automatically configure an electro-acoustic instrument tract

• The device is equipped with a clock, calendar, temperature gauge and meter voltage and battery current.

| Technical Specifications | |

| Methods of ultrasonic inspection | echo, echo-shadow, mirror, mirror-shadow |

| mode | The flaw detector, thickness gauge |

| indicator flaw | color matrix TFT display of 320 * 240 pixels |

| The range of products from steel sounding echo method | 2 ÷ 6000 mm (steel) |

| frequency band | 0.6 – 12 MHz |

| sensitivity adjustment range | 100 dB |

| Time sensitivity adjustment | 2,000 points (range, 80 dB) |

| Overall dimensions of flaw detector | 185 × 125 × 80 mm |

| Weight with battery | 1.3 kg |

| Operating temperature range | -10 ° ÷ + 50 ° C. (When operating the unit in the heat shield the lower limit of the operating temperature range is reduced to -30 ° C) |

| The upper humidity value | 98% at 35 ° C. |

| Climatic performance and category of products | IP 67 |

| Interface connection to a PC | USB 2.0 |

| Clock and Calendar | Yes |

| Alarm clock | Yes (2 pcs) |

| Display unit of temperature | Yes |

| Battery (4pcs) | NiMH,, type D, capacity 10 Ah |

| Time of continuous operation on battery power | 12 hours |

| Mains power supply | SP-9414 (50 or 60 Hz, 160 ÷ 240) |

| Auto power off under reduced network voltage (less than 160V) | Yes |

| The scheme of protection against short-circuit | Yes |

| Simultaneous power to the unit and the battery charge | Yes |

| Battery charge time | 5:00 (when the device is switched off UD9812) |

| Power consumption of AC | no more than 20 W. |

| Voltage Display and charge current (discharge) of the battery | Yes |