We are Manufacturer, Supplier, Distributor, Trader, Exporter, Importer, Maintenance Ultrasonic Thickness Gauge and our setup is situated in Pune, Maharashtra, India.

Ultrasonic thickness measurement is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element. This type of measurement is typically performed with an ultrasonic thickness gauge which adopts ultrasonic measuring principle, and is controlled by a microprocessor, provides quick and precise measurement of thickness for most of the industrial material.

ADVANTAGES :

• Non-destructive technique

• Does not require access to both sides of the sample.

• Very high accuracy.

• Does not require access to both sides of the sample.

• Engineered to cope with coatings, linings, etc.

• Does not require laboratory conditions.

B2 -General purpose Ultrasonic Thickness Gauge) B6 - C Ultrasonic Thickness Gauge with A-Scan and B-Scan

• Of products from metals and their alloys;

• Under protective coatings:

• Of non-metallic products (plastic, ceramics and other).

PURPOSE:

• Thickness measurement:

• Of products from metals and their alloys,

• Under protective coatings:

• Of non-metallic products (plastic, ceramics and other)

FEATURES:

• Metal thickness measurement under coating (In ECHO-ECHO mode and PULSE-ECHO-COATING mode):

• Coating thickness measurement (in PULSE-ECHO-COATING mode)

• Colour display (TFT 2.4", 320 0 240)

• ECHO signal graphic display in A-scan mode and B-scan

• High Memory

• Automatic probe recognition

• High accuracy and reliability

• Wide range of wear resistant and dual crystal transducers

• High Temperature Measurement

MK4-C COATING THICKNESS GAUGE

PURPOSE: Small-sized device for operative coating thickness measurements of paint, lacquer, galvanic, powder, bitumen and other coatings on substrates from ferrous and non-ferrous materials with increased temperature range.

FEATURES:

• Colour OLED display with 1.7" diagonal, large digits on display;

• Device can be delivered with integrated combined small-sized probe for measuring coating thickness

on substrates from ferrous and non-ferrous materials;

• Increased temperature range up to -30 °C;

• Possibility of tolerance mode measurement, measuring with averaging:

• Device can be delivered with integrated probe or with built-in probe on cable

BASIC TECHNICAL FEATURES:

• Parameter Model: - MK4-C

• Range - 0 p - 30mm

• Resolution - 1 µ

• Accuracy - 0 to 500p ± (2% + 1µ)

• 500µ to Tmax ± 2%

• Memory - NO

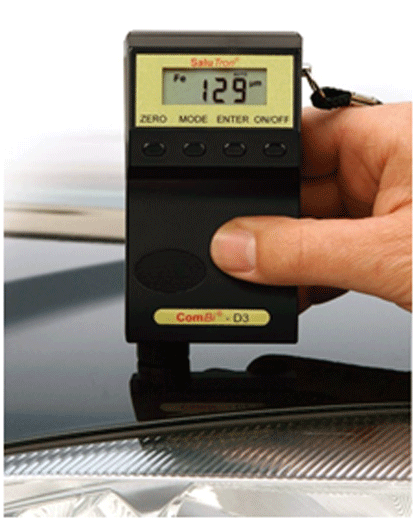

Combined coating thickness measurement on ferrous and non-ferrous substrates (Fe-NFe)

The gauge allows the user to make all the necessary adjustment with the aid of a menu – changes can therefore be implemented quickly and simply with a minimum amount of fuss. These features as well as others, make the practical hand-held pocket-sized gauge an indispensable aid in the quest for quality control and other applications, where ease of use and high-speed measurements with impeccable accuracy are desired.

ComBi D3® measures all non-magnetic coatings such as synthetics, lacquers, enamels, copper, chromium, zinc, etc. on steel or iron and all isolating coatings such as lacquers, synthetics, enamels, paper, glass, rubber, etc. on copper, aluminium or brass. This includes eloxal coatings on aluminium as well.

FEATURES:

• Easy to use

• Large measuring range – 0 to 3.5 mm

• High accuracy:

• ± (1 µm + 2%) from 0 – 999 µm

• ± 3.5% from 1000 – 3500 µm

• Measurement type – single-point or continuous

• Vibrations do not influence the measurement

• Wear resistant, spring-loaded ruby probe

• Measurement result can be displayed in µm/mm or mils

• Gauge can be switched on/off manually or automatically

• Visual alarm if the coating thickness exceeds the maximum range

• Integrated probe – for single-handed use

• Easy set-up – just follow the menu

• Requires no timely re-calibration for different materials

• The V-groove assists in the placement of the probe on spherical surfaces (eg. rods, pipes, etc.)

| Product Details | |

| Measuring Range | 0 – 3500 µm or 0 – 140 mils |

| Resolution | 0.1 µm/1 µm/0.01 mm Or 0.01 mil/0.1 mil/1 mil |

| Minimum Thickness of Base Material | Fe: 0.20 mm or 8 mil, NFe: 0.05 mm or 2 mil |

| Accuracy | ± (1,5 µm + 2%) from 0 – 999 µm, ± 3.5% from 1000 – 5000 µm |

| Memory | ComBi D3: None ComBi D3plus: 8192 storage cells |

| Warranty | 24 Months |

The gauge SaluTron® D4 measures all non-magnetic coatings such as sythetics, lacquers, enamels, copper, chromium, zinc, etc. on steel or iron.

The gauge SaluTron® D5 measures all isolating coatings such as lacquers, synthetics, enamels, paper, glass, rubber, etc. on copper, aluminium or brass. This includes eloxal coatings on aluminium as well

FEATURES:

• Easy to use

• Large measuring range -0 to 5 mm

• High accuracy

• Measurement type-single-point or continuous

• Vibrations do not influence the measurements

• Wear resistant, spring-loaded ruby probe

• Measurement result can be displayed in µm or mils

• Gauges can be switched on/off manually or automatically

• Visual alarm if the gauge is placed on incorrect substrate or if coating thickness exeeds the maximum range

• Integrated probe-for single-handed use

• Easy setup

• Requires no timely re-calibration for different material

• The V-groove assists in the placement of the probe on spherical surfaces (rods, pipes, etc.)

| Product Details | |

| Measuring Range | 0 - 5000 µm or 0 – 200 mils |

| Resolution | 0.1 µm/1 µm/0.01 mm Or 0.01 mil/0.1 mil/1 mil |

| Minimum Thickness of Base Material | Fe: 0.20 mm or 8 mil, NFe: 0.05 mm or 2 mil |

| Accuracy | ± (1,5 µm + 2%) from 0 – 999 µm, ± 3.5% from 1000 – 5000 µm |

| Memory | D4/D5: None, D4plus / D5plus: 8192 saving slots |

| Warranty | 24 Months |

To the promising concept of the proven SaluTron® D1 and the enhanced SaluTron® D2X coating thickness gauges, belong not only high precision of measurements, but also the absolute easy and reliable operation. You can carry out all options easily and quickly through the leading menu on the display. Additionally all gauges are waterproof against splash’s rain and most solvents – corresponding to IP 65

FEATURES:

• Waterproof under IP Code 65

• Easy operating and setup by leading menu

• Quick zeroing and calibration of the gauge

• Setup units of measurement: µm or mil

• High accuracy

• Continuous measurement possible

• V-groove enables measurements on axes or staves

• Automatic probe detection

• Setup of language: English or German

• Automatic switch off

• Low battery warning indication

• Display backlight

| Product Details | |

| Measuring Range | Fe : 0 – 2000 µm, (0 – 2 mm) or 0.00 – 80 mil NFe : 0 – 800 µm, (0 – 0.8 mm) or 0.00 – 32 mil |

| Resolution | Fe: 0.1 µm/1 µm/0.01 mm Or 0.01 mil/0.1 mil NFe: 0.1 µm/1 µm Or 0.01 mil/0.1 mil |

| Minimum Thickness of Base Material | Fe: 0.20 mm or 8 mil, NFe: 0.05 mm or 2 mil |

| Accuracy | ± (1.5 µm + 2%) or ± (0.06 mil +2%) |

| Memory | D1: None,

D2: 8192 Locations |

| Warranty | 24 Months |